Raw Material: The raw material for the supply of duct profiles will be made of Lock forming grade GI material having 120GSM coating. The raw material used will be in Coil form of 1220mm width. Different material like aluminum / Galvaaluminum can also be used for manufacturing duct profiles depending upon requirement.

Duct Connectors and Accessories: All transverse duct connectors (flanges/cleats) and accessories/related hardware such as support systems shall be zinc-coated (galvanized).

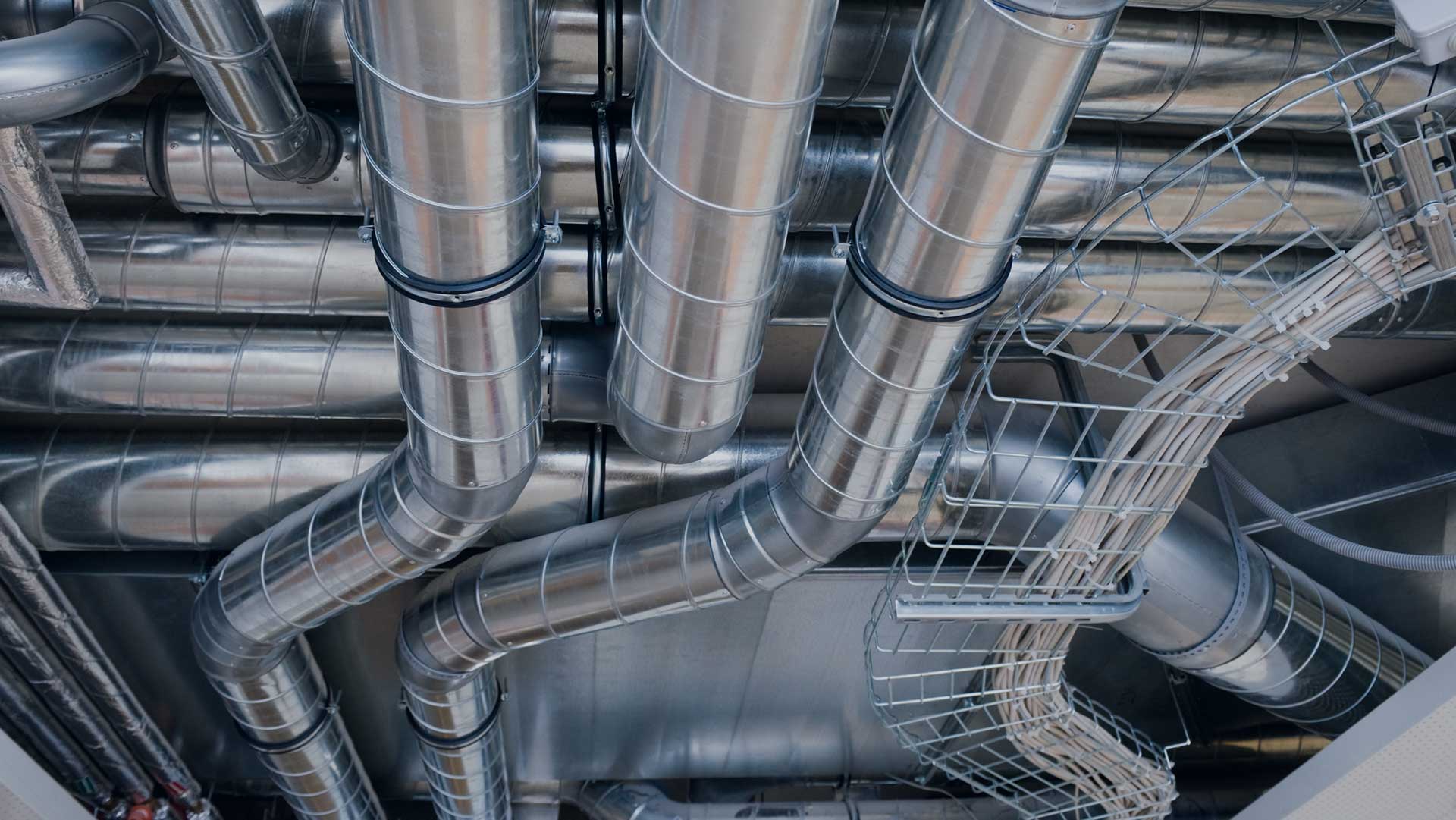

FABRICATION STANDARDS: All duct profiles including straight pieces, tapers, elbows, branches, shoe pieces, collars, terminal boxes and other transformation pieces will be made on Cool Freez Systems Pvt.Ltd. Ltd. factory-fabricated technology. The following machines and processes to provide the requisite quality of ducts and speed of supply:

COIL LINE: Coil lines to ensure location of longitudinal seams at corners by providing notches /folded edges to obtain dimensional accuracy and provides beading along the length of ductwork to ensure the required duct rigidity and low leakage characteristics.

PLASMA MACHINE: All ducts transformation pieces like elbows, tapers and fittings are made on CNC profile cutting machine for required accuracy of dimensions, location and dimensions of notches at the folding lines.

ROLLFORMING MACHINES: All edges are processed on roll forming machines to form longitudinal seams and transverse joints and roll-bending for turning up edges. All transverse joints shall be the TDC type flanges system or Dive cleat or equivalent makes of similar 4bolt systems.